Using natural smoke preparations in meat processing provides manufacturers with a wide range of benefits – first and foremost, a distinctive taste and authentic smoky aroma.

When polymer casings are used, achieving the desired smoking effect by traditional methods is often challenging. With Royal Spice natural smoke condensates, the solution is simple: they can be incorporated directly into the meat mix during curing, or applied at the final stage of production.

Our specially developed Aromagold series smoke flavors are widely used in the production of cost-effective sausages stuffed into polyamide casings. Aromagold blends are compatible with all protein types and work seamlessly with nitrite and other functional additives. For premium sausages, atomization or surface application onto natural casings is recommended, ensuring an intense smoky flavor and a rich, appealing color in record time.

To achieve an attractive smoked color, we created KoptiSmak dye. Unlike conventional food colorings (such as annatto, tartrazine, or sunset yellow), KoptiSmak provides key advantages:

- Uniform coloring without streaks or blotches, regardless of raw material quality

- Produced from natural oak, alder, and cherry smoke condensates

- Strong adhesion to the product surface

- Simple and convenient application

- Reduction of smoking chamber time while boosting product yield by up to 10%

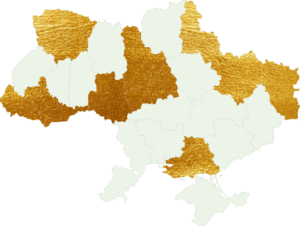

Thanks to close collaboration with research institutions and leading Ukrainian meat-processing technologists, Royal Spice has developed advanced smoking solutions that balance both production efficiency and consumer expectations.

Benefits of Smokeless Smoking:

? Finished product yield increased by up to 10%

? Perfectly uniform smoked color

? Longer shelf life

? Reduced smoking time — in some cases, traditional smoking can even be skipped

? Higher production volumes without additional equipment

? For samples, recipes, and application methods tailored to your specific products, please contact our technologists at Royal Spice.